Solutions Built Around Your Vision

From prototype to production.

When off-the-shelf components fall short, Kowa delivers custom imaging solutions designed to address your unique performance and environmental requirements. Whether you need modified optics, sensor-to-lens positioning, or a fully bespoke system, our technical experts collaborate with you to develop technologies that meet real-world demands.

We help resolve challenges where space constraints, harsh operating conditions, wavelength sensitivity, or mounting limitations make conventional offerings impractical. Drawing on more than 75 years of experience in optical engineering and mechanical innovation, we manufacture assemblies that match seamlessly with your specifications while upholding the same high standards of quality, consistency, and long-term support found across our broader product portfolio.

Commonly Requested Options

- Specified focal lengths and field-of-view.

- Optimized optical coatings including NIR, SWIR, anti-reflective, and more.

- Specialized mounts and flange back adjustments for camera compatibility.

- Turnkey assembly of camera, sensor, and lens modules.

- Housing upgrades such as ruggedization, compact form factors, fixed iris or focus options, and robust locking mechanisms.

- Environmental protections including shock and vibration proofing, waterproofing, and resistance to dust, oil, and radiation.

- Private labeling and dedicated part numbers for OEMs.

Adapting Standard Catalog Models with Targeted Improvements

-

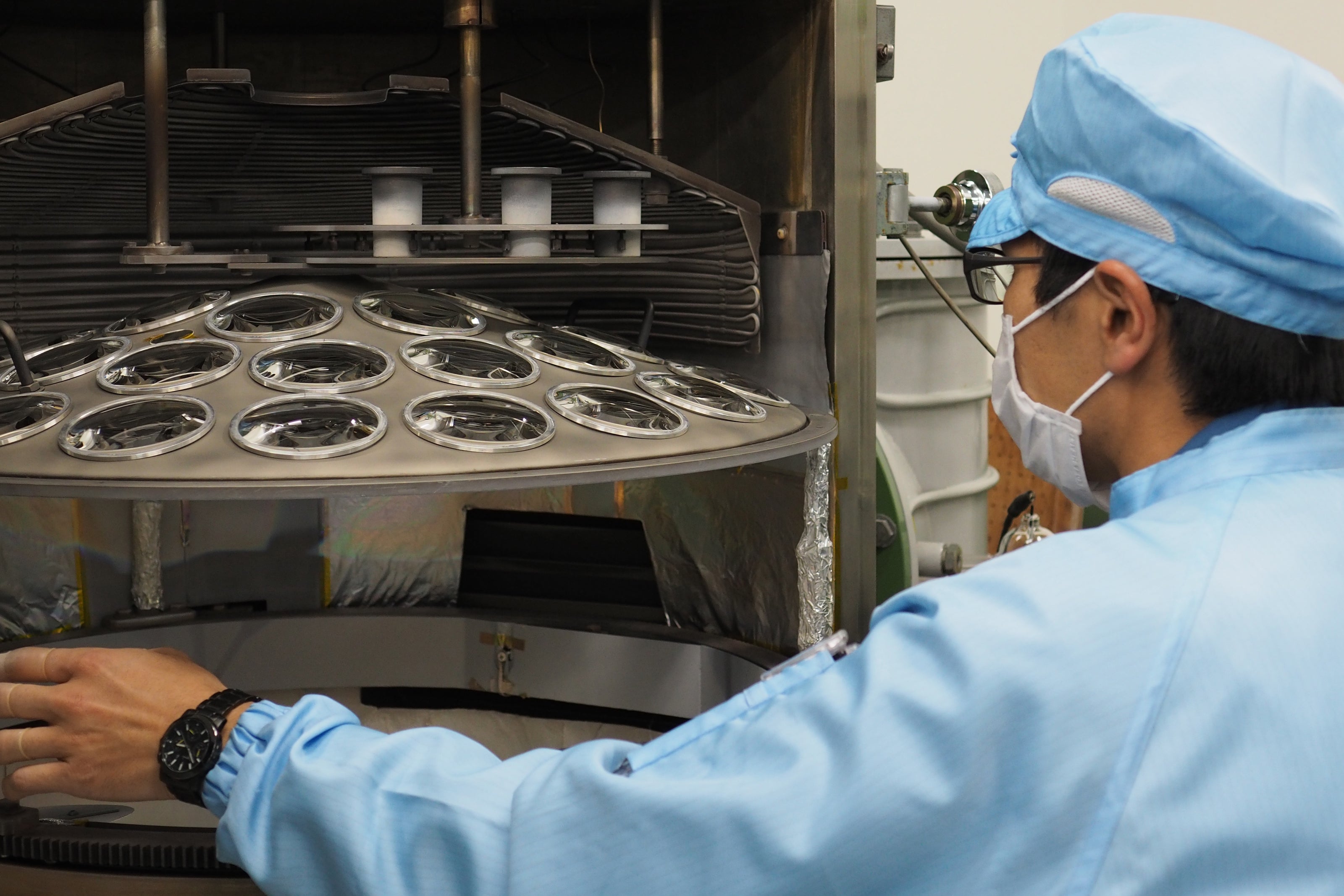

Coating Enhancements

We apply special AR, NIR, SWIR, or hydrophobic coatings to satisfy a range of objectives, including increasing light transmission, reducing reflection, minimizing ghosting, boosting contrast, and protecting the lens surface.

-

Mechanical Refinements

We adjust components such as housings, apertures, and mounts to achieve tight integration with your system. From reducing the footprint to applying a fixed iris or focus, each part is configured to suit your application.

-

Reinforced Glass Bonding

Internal glass elements are securely bonded with adhesive to maintain optical alignment and strengthen structural integrity, ensuring reliable performance under physical stress and environmental exposure.

Complete Custom Design and Delivery

For imaging demands that standard products can’t meet.

Step 1: Application Review and Consultation

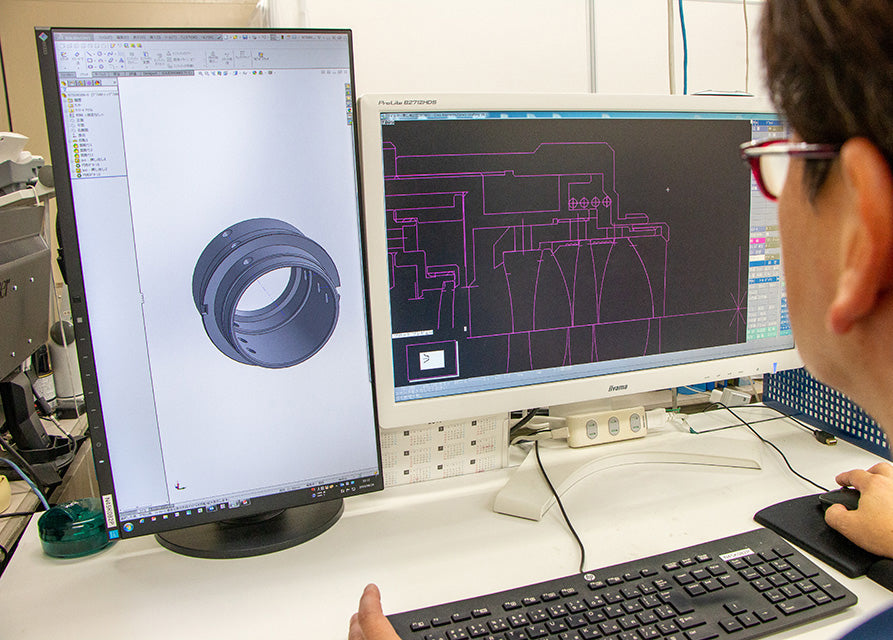

We work closely with you to understand your project requirements, system constraints, and performance targets. Our team carefully balances optical and mechanical factors while keeping your target cost and timeline in mind.

Step 2: Solution Proposal

Building on our collaboration, we craft an initial plan aligned with your technical objectives, defining key imaging parameters, mechanical considerations, and a clear path to feasibility.

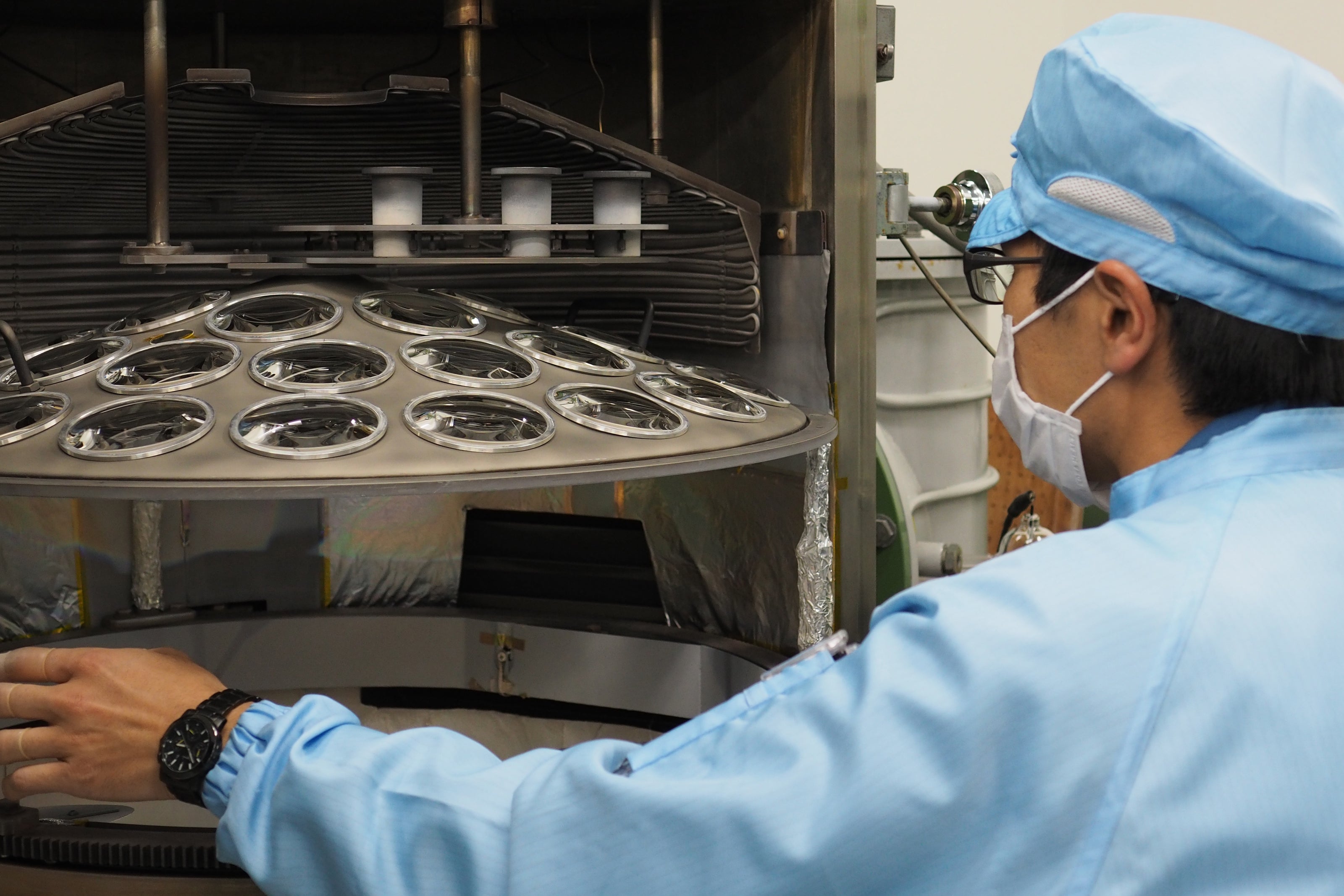

Step 3: Prototyping and Evaluation

With concept approval in place, we build and test a prototype to validate functionality under real-world conditions. This phase includes feedback-driven revisions to ensure optimal system integration and imaging results.

Step 4: Production and Ongoing Support

After successful testing, we transition to full-scale production. Your custom lens, camera, or integrated unit is manufactured to exact specifications, typically within three to six months. Following initial procurement, we continue to provide you with status updates, additional units, and modifications as your needs evolve.

Want Input on Specs, Fit, or Integration?

Whether you are seeking help with orders, have questions about service, or require custom configurations, our experienced technicians are here to guide you toward the right solution.