Lenses and Cameras for Robotic Applications

Choosing appropriate machine vision lenses and cameras is essential for optimizing the performance of industrial automation systems. As robots evolve and become more advanced, their capacity to perceive and engage with their surroundings plays a critical role in enhancing productivity and precision. Machine vision, particularly with the integration of cutting-edge 3D vision technologies, allows robots to execute intricate tasks with both accuracy and efficiency.

Common Applications of Robot Control Vision Systems.

Machine vision lenses/cameras play a crucial role in a variety of robot control tasks, such as:

- Precise location identification for pick-and-place operations

- Guiding robotic movements

- Tracking components on conveyor belts

- Bin picking and object sorting

- Automated palletizing and depalletizing

- Assisting collaborative robots in navigation

- Providing guidance for assembly of components

- Inspecting products and large sub-assemblies

- Supporting healthcare and medical robotic systems

The Influence of High-Quality Lenses/Cameras on Robotic Performance.

The selection of lenses/cameras significantly affects object detection and overall system efficiency. High-quality lenses deliver high-resolution imaging for identifying even the smallest defects, offer durability suited for industrial environments, ensure adaptability to different lighting conditions, and provide resistance to shock and vibration, ensuring reliable and consistent performance.

Designed for Shock and Vibration Resistance.

Cameras and lenses used in robotics must endure constant shock and vibration. Kowa provides ultra-compact lenses that enhance vibration resistance due to their reduced size and weight. Additionally, Kowa's ruggedized lens series takes this a step further, featuring glued glass elements, double-nut thread focusing rings, and variable step-up rings for different aperture adjustment. Kowa also designs its cameras to meet shock and vibration resistance standards, ensuring stable imaging without pixel shift even in high-vibration environments. Furthermore, Kowa offers customized solutions to make other lens series resistant to shock and vibration, broadening their range of applications.

Lenses suitable for automation and robotics.

-

LM8JC5MC-WP

Regular price $546.00Regular price -

LM12JCM-WP

Regular price $380.00Regular price -

LM25JCM-WP

Regular price $410.00Regular price -

LM50JCM-WP

Regular price $380.00Regular price -

LM16JCM-WP

Regular price $380.00Regular price -

LM35JCM-WP

Regular price $380.00Regular price

Packaging

The packaging industry requires accurate and efficient inspection systems to ensure product integrity. Kowa lenses/cameras enhance machine vision systems that check for packaging defects, verify labels, and ensure seal integrity. This helps maintain product quality and reduces waste.

Pharmaceuticals

In the pharmaceutical industry, precision and reliability are crucial. Kowa industrial lenses enhance machine vision systems used in the inspection of drug packaging, labeling, and tablet quality. These lenses ensure that every product meets stringent regulatory standards, preventing contamination and ensuring patient safety.

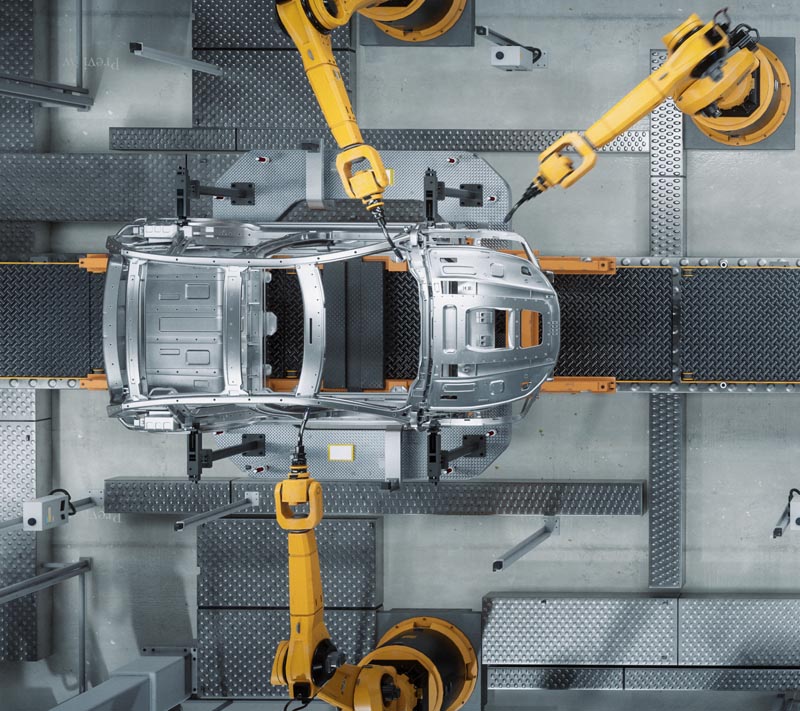

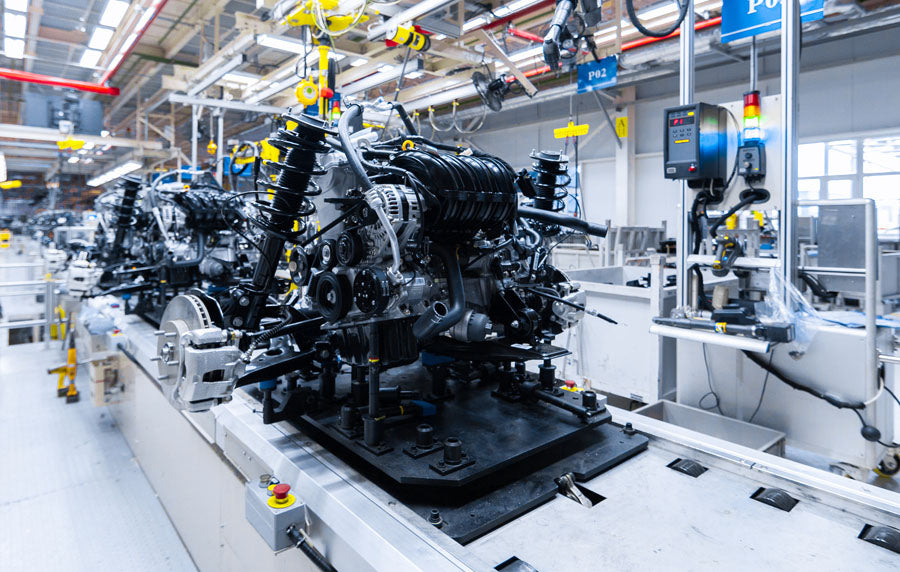

Automotive

The automotive manufacturing industry relies on machine vision for quality control and assembly verification. Kowa industrial lenses deliver the precision required to inspect components, detect defects, and ensure correct assembly. This leads to enhanced product reliability and manufacturing efficiency.

Food and Beverage

Ensuring food safety and quality is paramount in the food and beverage industry. Kowa industrial lenses are integral to machine vision systems that inspect packaging, detect contaminants, and verify labeling. These lenses help maintain high standards of hygiene and compliance, protecting consumer health.

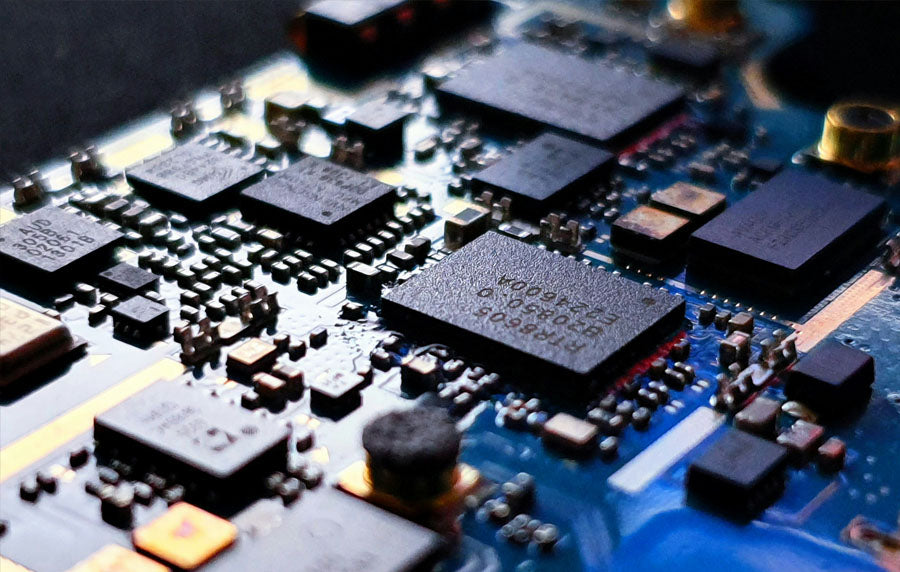

Electronics and Semiconductor

In the electronics and semiconductor industries, microscopic precision is essential. Kowa lenses provide the high-resolution imaging needed for inspecting circuit boards, detecting defects, and aligning components. This ensures the production of high-quality electronic devices and components.