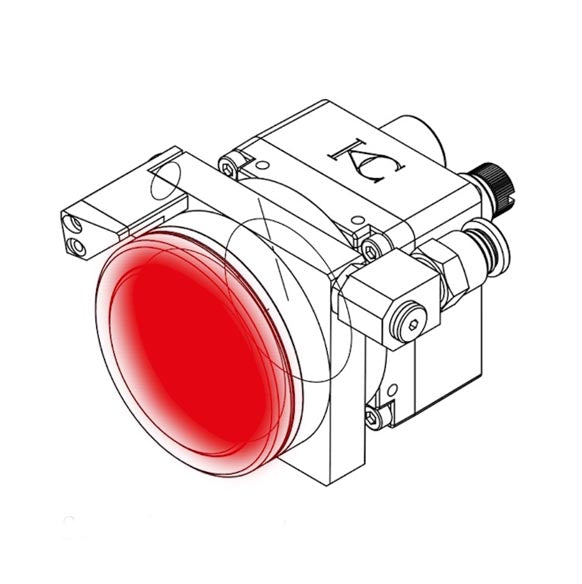

Rotary Wiper

ROTARY WIPER: IMPROVING CNC WORKFLOW

Machine tool manufacturing is highly demanding due to the need for precise programming and strict tolerances to achieve accurate, high-quality output. Regular monitoring of machine performance is essential to maintain these standards and avoid errors or production delays. The complexity of CNC manufacturing often obscures real-time visibility into the process, making manual inspection critical. However, frequently stopping CNC machines for checks, while necessary to ensure precision, can lead to delays and disrupt the continuous production flow.

With Rotary Wiper - CNC workflow is dramatically improved:

- Detect blind spots typically undetectable from outside the CNC machine environment.

- Quickly identify potential manufacturing issues, such as steel chip accumulation, before they occur.

- Monitor live manufacturing and record data to ensure consistent results and optimize production.

- Assess manufacturing processes without the need to stop the CNC machine.

- Compact design and easy installation.

With Rotary Wiper - CNC workflow is dramatically improved:

> See blind spots usually undetectable from outside of the CNC machine environment.

> Quickly detect possible manufacturing issues before they happen such as steel chip accumulation.

> Monitor live manufacturing and record data to ensure consistent results and improve production.

> Monitor and assess manufacturing without the need to stop the CNC machine.

> Compact size and easy to install.

-

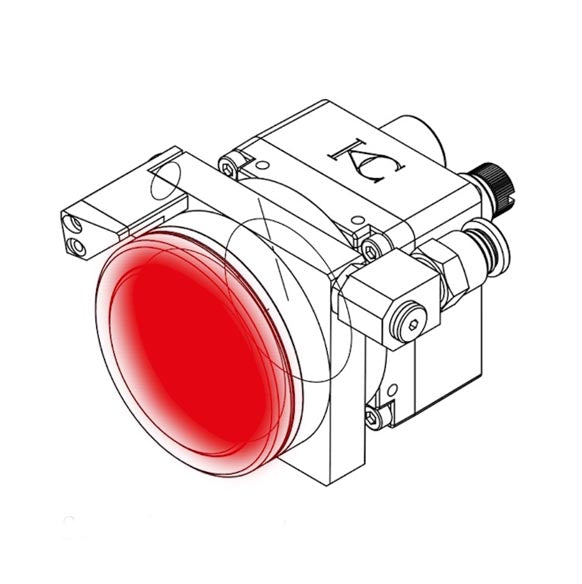

UNIQUE KR COATING

Scratch resistant sapphire glass and Kowa’s KR coating actively repels moisture, oil and residue from building on the surface of the lens housing.

-

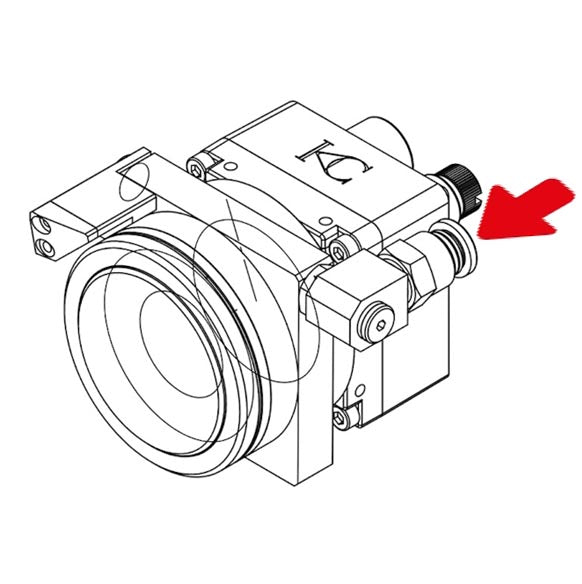

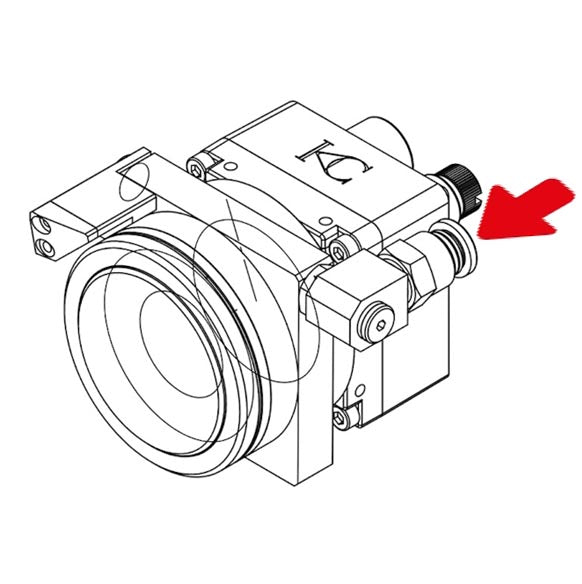

AIR INJECTION

A constant stream of high pressure air not only rotates the wiper but also helps to remove moisture and oil particles.

-

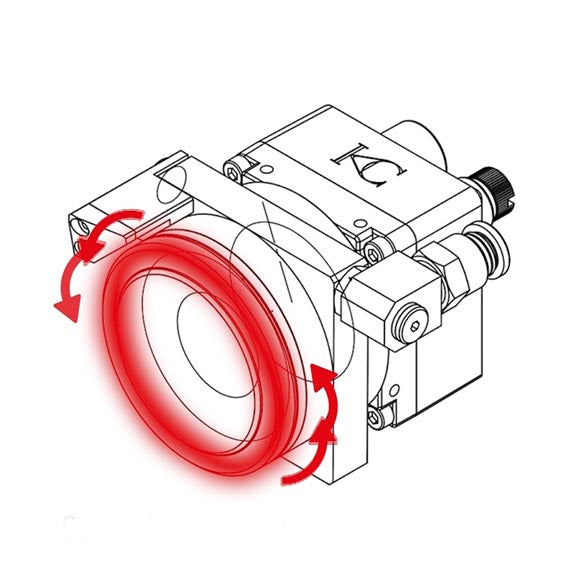

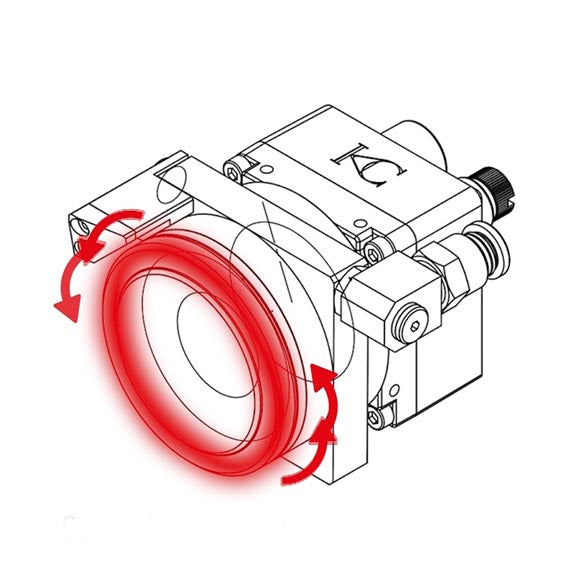

ROTATION

The high speed rotary wiper powered by air injection removes any remining material for a consistent clear view.